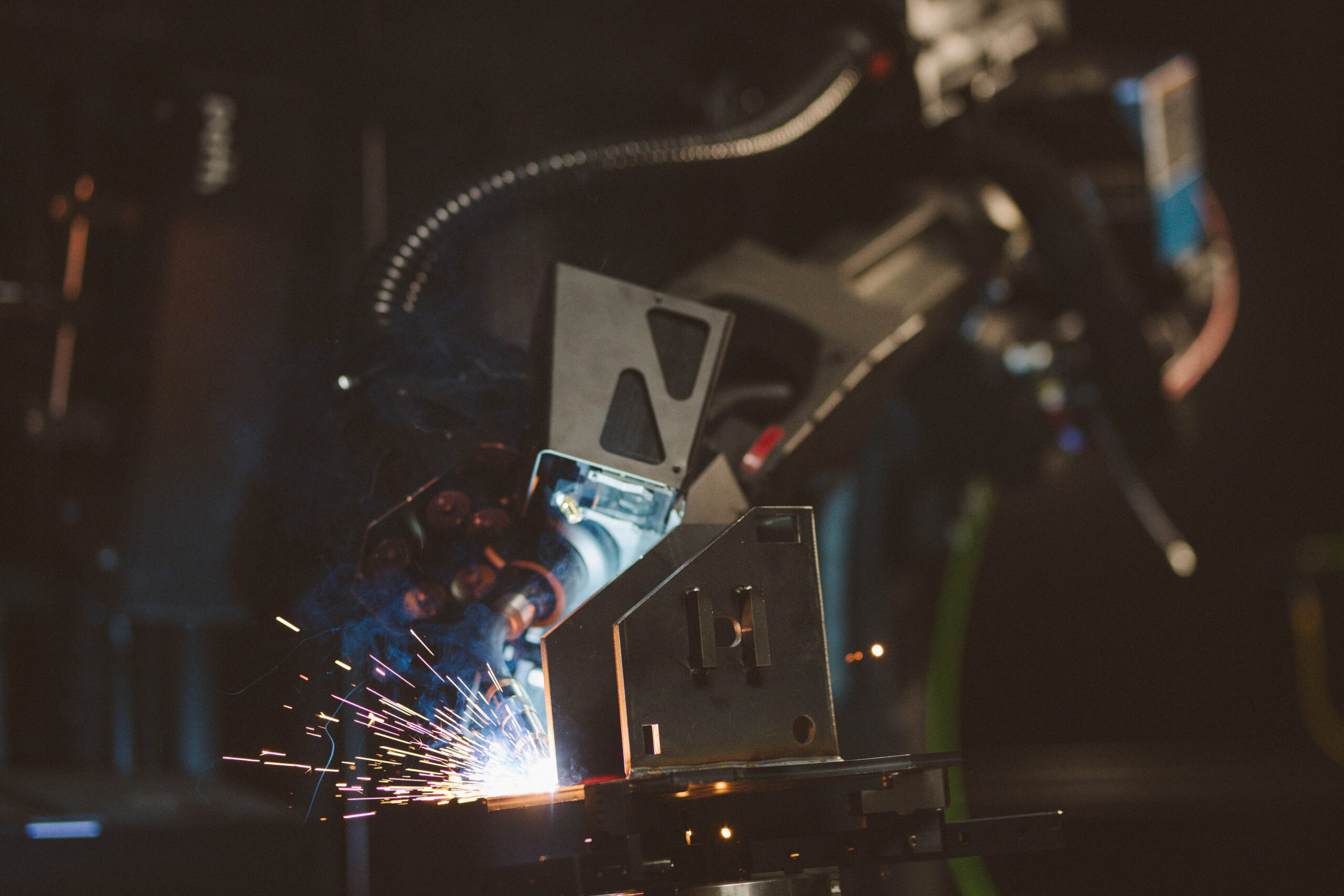

Your welder shortage

is over.

Path’s robotic welding systems help you hit your production goals, even as the welder labor shortage continues. Automate your shop floor, achieve quality welds and get product out the door.

Generate revenue, reduce risk, increase profit

Optimize your shop floor with the most advanced robotic welding systems, all without spending millions on CapEx. Path robotic welders deliver consistent quality to get your projects out the door with speed, augmenting the work of your experienced welders and protecting you from the labor shortage.

Program parts in hours, not days

It’s about flexible and adaptable welding. Leave teach pendant programming in the past. Simply upload your CAD models to JobBuilder™, identify weld seams and automate motion planning. No trained programmer required.

Accurately weld irregular parts

Our AI vision model learns from every weld our robots complete. Which means it brings a ton of experience directly to your shop. No drug test required.

Troubleshoot remotely, 24/7

Mission Control is your all-access pass to PATH’s U.S.-based automation maintenance team. Day or night, we’ll monitor your cells, take care of routine maintenance, and address bigger problems before they cause downtime.

First pass yields near 99%

Get a consistent, high-quality weld every single time. Even for applications with extremely tight tolerances like in energy and infrastructure, transportation and defense.

How? Our advanced computer vision automatically recognizes and adjusts to part variability. And our AI learns from each weld it completes. Together, this creates precise and efficient autonomous welding systems.

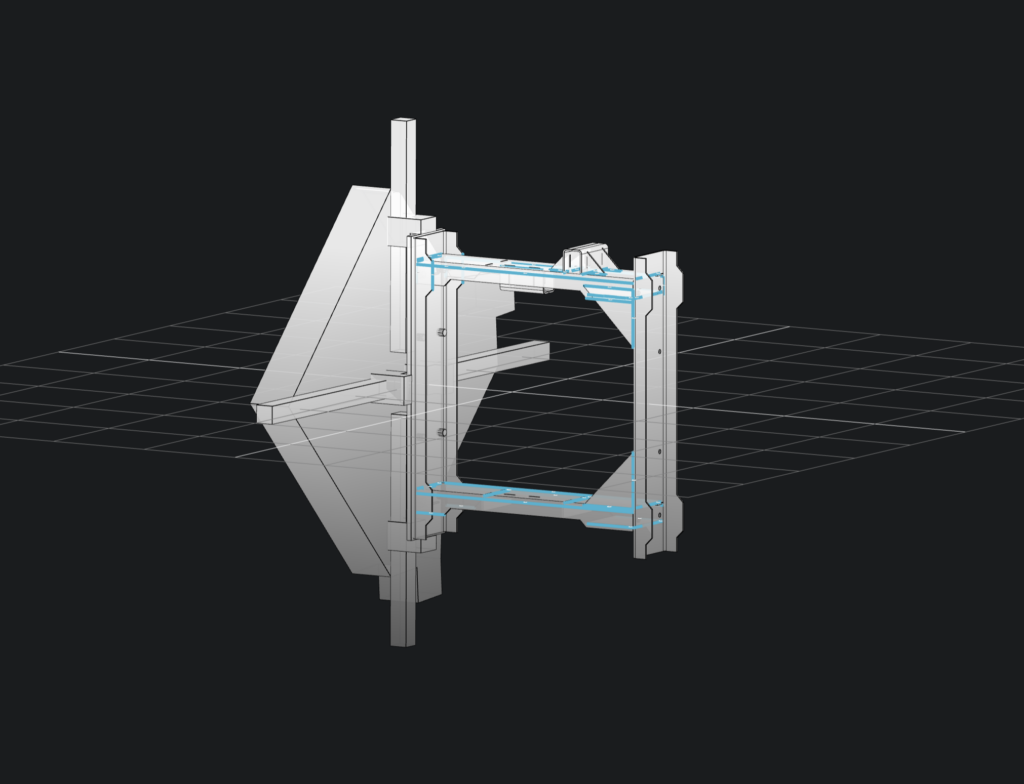

AW-3 welding robot

Tackle big projects with the AW-3 welding robot. Made for parts with over 1,000 inches of welding, this robot handles finish welding for high mix, medium-volume applications.

- Safer material handling: Big, heavy parts are expensive to handle and can be dangerous for welders to work on. Let a robot do it instead.

- Shorten your weld cycle: Take manually operating a crane out of your cycle time. The AW-3 can move your heavy parts for you.

AF-1 welding robot

The AF-1 is ideal for manufacturers that do a high volume of small parts. This welding robot can pick, fit-up, tack, and finish — all with no manual loading or unloading.

- Eliminate one-off expenses with built-in modular fixturing

- Handle five to 10 SKUs with ease

- One operator can oversee multiple cells

Work with Path Robotics

This is your competitive advantage. Take it.

Hit your production goals with an autonomous robotic welding system.

Tell us about your current operation and where you see it heading. We’ll prove quality and ROI. Fill out this form and our team will get back to you within 24 hours.